Hotline:

+86 13621506607

Hotline:

+86 13621506607

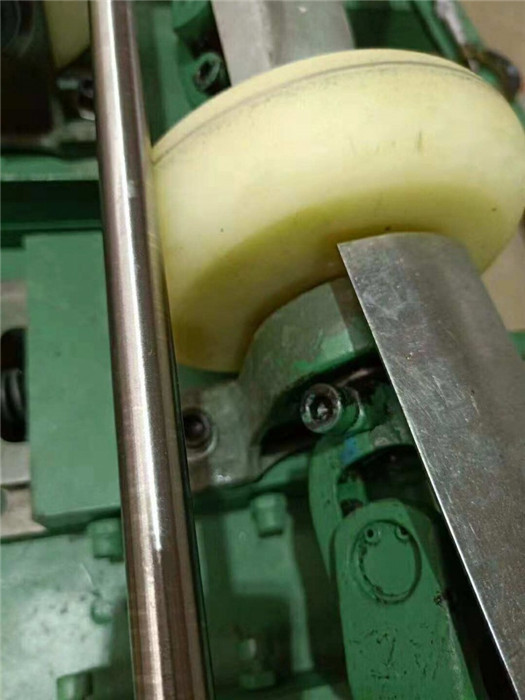

Material: 9cr18Mo

Ingredients:

C Si Mn P S Cr Ni Mo V Cu Nb N

0.95 to 1.10 ≤0.8 ≤0.8 ≤0.040 0.03 16 to 18 0.6 0.4 to 0.7 is allowed

Heat treatment system:

Annealing: 800 ~ 920℃ slow cooling HBW ≤269

Quenching: 1000 ~ 1050℃ oil cooling

Tempering: 200 ~ 300℃ oil, air cooling HRC can reach 55

Standard: GB/T 1220-1992

● Characteristics and scope of application:

Due to the high carbon content in the steel, it has a high hardness and wear resistance after quenching, and has excellent rust and corrosion resistance in the atmosphere, water and some acid and salt aqueous solutions, and it is more obvious when the steel contains molybdenum. It is used to manufacture cutting tools, cutting tools, surgical blades, bearings, valves and other parts that are subjected to high friction and work under corrosive media conditions.